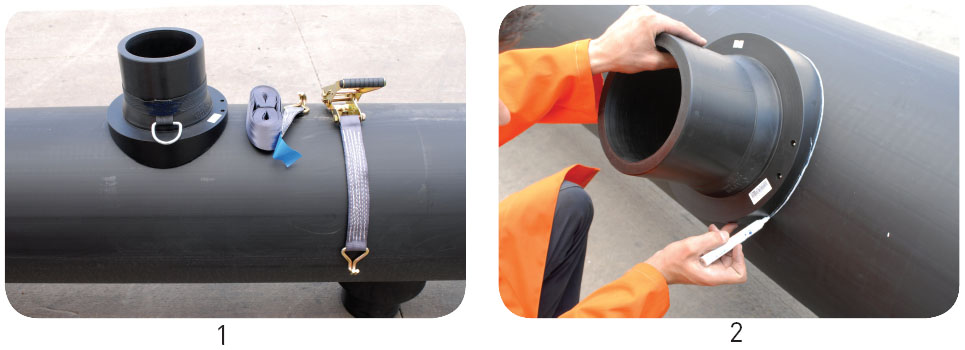

1- EF Saddle and belts before welding.

2- Put the EF Saddle on the welding point of pipe and draw interior and exterior circles.

3- Make a 10mm hole on the interior circle by the help of a drill.

4- Pierce the pipe from starting the hole which was opened with an electrical saw as shape of the interior circle.

5- Drilled hole

6- Scrape the thick field between interior and exterior circle to get the oxide layer on the pipe.

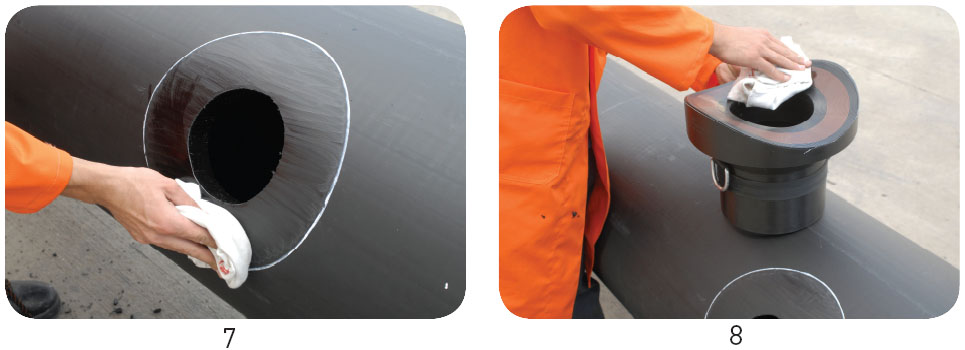

7- Clean the area that you was scroped before with an appropriate chemical. (Isopropyl alcohol)

8- If it is necessary. EF Saddle must be cleaned with an appropriate chemical before welding.

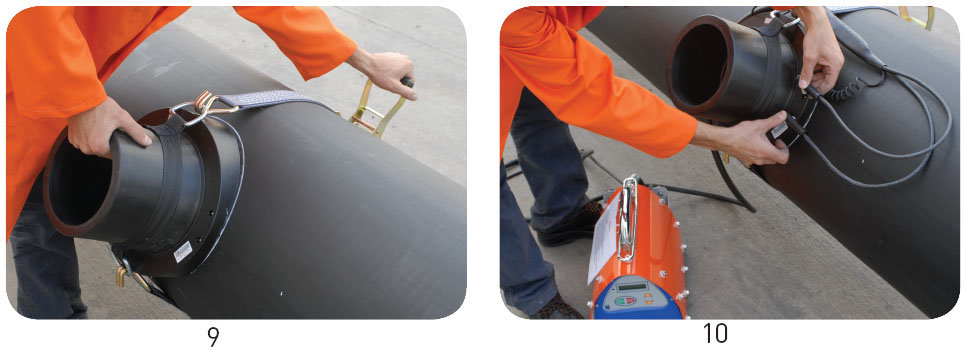

9- Press the EF Saddle strongly by the help of strap. Fix the EF Saddle on pipe as seen in the picture. Be sure that the internal diameter of EF Saddle is on the top of the hole on the pipe.

10- Put the adaptor pins of EF welding machine on EF Saddle and load welding data to EF welding machine by the help of barcode reader.

11- After the welding was completed, you should not take out strap system up to cooling duration. During this waiting time, EF welding machine can be used for another process.

12- Take off the straps after cooling.